In today’s world, safety and durability go hand in hand when choosing fabrics. One material that stands out for its protective and versatile properties is Flame Retardant Polyester. Known for its Fire Resistant, Strength, and Longevity, this fabric is widely used in industrial work wear, home furnishings, public space, and transportation sectors.

This guide will look at all the essential aspects of Flame Retardant Polyester Fabric. It focuses on the Composition, Properties, Uses, Advantages, and Care Instructions. This article is designed for manufacturers, designers, and end-users to enable safer and smarter fabric choices.

🔥 What Is Flame Retardant Polyester?

Flame retardant polyester (FR polyester) is designed to be a synthetic fabric that is resistant to burning and slows down fire spread. Unlike ordinary polyester, it is treated or manufactured with flame-resistant chemicals, which enhances its thermal stability.

There are two main ways to create flame retardant polyester:

- Inherent Flame Retardant Polyester– The polymerization process includes fire-resistant properties so that protection cannot be washed or worn out.

- Treated Flame Retardant Polyester – The fabric is finished with a flame retardant coating after production. It is effective, however, it does fade with washing or sun exposure.

In both cases, polyester is made less flammable, is able to self-extinguish when fire is present and does not melt or drip. Read more…Top Uses of Polyester Fabric

🧵 Composition and Structure

Flame retardant polyester does retain the core chemical structure of polyester (polyethylene terephthalate or PET) but is enhanced with special additions such as phosphorus-based compounds, antimony oxide, and halogen-free retardants. These compounds increase the limiting oxygen index (LOI) which determines the amount of oxygen that can be sustained to aid in combustion.Considering that normal air is composed of approximately 21% oxygen, materials that have an LOI of 26% and higher can be referred to as flame retardant. Most FR polyester fabrics have an LOI within this applicable range, ensuring cultivable fire resistance.

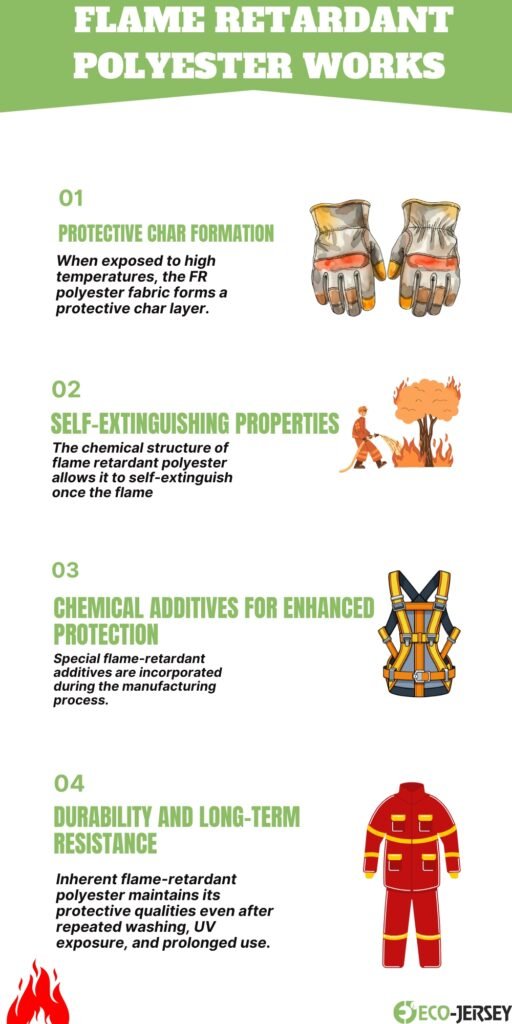

🌡️ How Flame Retardant Polyester Works

The fire-resistant performance of flame retardant polyester fabric highly relies on several factors which influence its response to heat and flame:

- The FR fabric produces and sustains a protective char, that insulates soft underlying fibers.

- The self-extinguishing FR fabric produces and sustains protective char layers.

- The chemical additives that fabricate the self-extinguishing FR fabric, which char and self-extinguish.

- The inherent FR polyester will maintain its protective levels, even after many washes or prolonged use.

Due to this reaction, flame-retardant polyester is an engineered safety fabric and signifies that flame-retardant polyester can be used in highly dangerous areas. Read more…History of Polyester Fabric

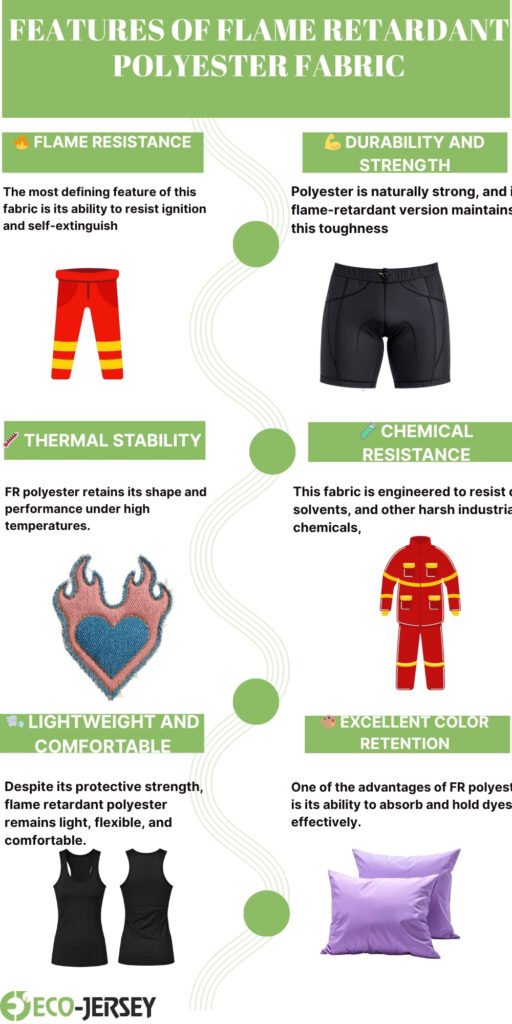

🧯 Key Features of Flame Retardant Polyester Fabric

Flame retardant polyester is valued for its balance of safety, performance, and practicality. Some of its most notable features include:

1. Flame Resistance

This is undoubtedly the most obvious feature. When polyester fabric is ignited, flame is withdrawn, and the polyester fabric will not burn, melt, or self-extinguish.

2. Durability and Strength

Polyester is strong, and flame-retardant polyester retains that strength. It holds up against wear and tear and withstands repeated washing.

3. Thermal Stability

FR polyester stands up to high temperatures, and retains its shape. This makes it useful for jobs that have heat exposure.

4. Chemical Resistance

This material resists burning oils, solvents, and many other industrial chemicals which prolong the life of the fabric and helps it perform consistently.

5. Lightweight and Comfortable

Even with its heavy-duty protection, flame-retardant polyester is light and comfortable enough for everyday wear and upholstery.

6. Color Retention

This fabric takes up and holds colors. Manufacturers can create vibrant, long-lasting colors in fire-resistant polyester materials.

🧰 Applications of Flame Retardant Polyester

Numerous industries depend on the versatility of FR polyester. Here are some of its most common uses:

1. Industrial Workwear

Flame-retardant polyester uniforms offer protection against sparks, flames, and heat exposure to workers in the oil, gas, electrical, and chemical industries.

2. Home Furnishings

FR polyester curtains, drapes, upholstery, and bedding help reduce the spread of fire in soft furnishings. This adds fire safety to residential and commercial spaces.

3. Public Spaces

To comply with safety standards, fire-retardant curtains, seat covers, and carpets are used in hospitals, theaters, schools, and hotels.

4. Transportation Industry

Passenger safety during emergencies is ensured with FR polyester used in airplane seats, train interiors, and car upholstery.

5. Protective Equipment

For added durability, polyester blends which are fire resistant are used in safety vests, fire blankets, and gloves.

🧪 Production and Treatment Process

There are several planned phases when making flame retardant polyester.

- Polymer Blending: During polymerization, flame retardant additives are incorporated.

- Extrusion: The mixture is spun and melted into fibers.

- Texturing: Texturing the fibers improves their strength and comfort.

- Weaving or Knitting: Fabrics are made by knitting or weaving the yarn.

- Finishing: Chemical coatings are added to the treated fabrics during this stage.

In addition, halogen-free finishes are now common due to their safety and adherence to standards such as OEKO-TEX® and REACH.

🌍 Environmental Considerations

Although polyester is synthetic, the impact of flame retardant technologies on the environment is less due to eco-friendly polyester.

- Halogen-free additives powerfully remove toxic emissions.

- Reusable industrial applications are available for recyclable FR polyester.

- Manufacturers have prioritized the implementation of sustainable FR treatments that provide the same benefits as conventional treatments but are biodegradable.

Thus, flame retardant polyester is now a more eco-friendly and responsible material that adapts to contemporary requirements.

💡 Advantages of Flame Retardant Polyester

The value of flame retardant polyester fabric goes beyond the mere fact that it is fire resistant. Some additional benefits of flame retardant polyester fabric are:

- Enhanced Safety: Provides trustworthy protection in hazardous situations.

- Long-Lasting Performance: Does not fade, and retains its strength.

- Cost-Effective: Its longevity translates to value over time.

- Low Maintenance: Simple to care for and dries quickly.

- Versatile Use: Can be used in clothing and in home furnishings.

- Compliance with Standards: Safety certification recognized in any region of the world.

The fabric’s preferred choice status in various industries, as well as for home use, is largely due to its ability to withstand various forms of stress and exposure.

🧼 Care and Maintenance of FR Polyester

To ensure that flame retardant polyester retains its protective attributes, it must be properly maintained:

1. Washing

Always use a mild detergent when washing flame retardant polyester. Avoid using bleach, harsh chemicals, or strong alkaline detergents, as these can break down the flame-retardant finish and weaken the fabric fibers.

2. Drying

When drying, it’s best to tumble dry on low heat or hang the fabric in a shaded, well-ventilated area.

3. Ironing

If ironing is necessary, use a low to medium heat setting (110–150°C / 230–300°F). Never press the iron directly onto the coated or printed side of the flame retardant fabric.

4. Storage

To maintain the integrity of the material, store flame retardant polyester fabrics in a cool, dry place, away from moisture and direct sunlight.

By adhering to the following care guidelines, you can help flame retardant polyester objects last longer and work better. Read more…How to Cool and Cut Polyester Fabric

📈 The Growing Demand for Flame Retardant Fabri

As the world focuses on workplace safety and sustainability, the need for flame retardant polyester is on the rise. FR textiles help the construction, oil and gas, hospitality, and public transport industries meet international fire safety standards.

Additionally, the demand for fire-safe home decor is growing. As a result, the textile industry has to develop new FR polyester blends that combine safety, comfort, and eco-friendliness.

🧠 Tips for Buyers and Manufacturers

- For consistent and long-lasting results, use inherent FR polyester.

- Check certification standards such as NFPA 701, EN ISO 11612, or BS 5867.

- For eco-safety, choose halogen-free options.

- Ensure you test for wash durability before purchasing in bulk.

- The branding could focus on “fire-safe,” “durable,” and “sustainable” attributes since they have good SEO rankings and customer attraction.

🧭 Conclusion

Flame retardant polyester amazed by modern textiles as it combines safety, durability, and comfort. Industries and households prefer it for its affordability, along with its ability to resist flames and survive in extreme conditions.

High-performance flame retardant fabrics are ever more in demand, and awareness of fire safety is rising. FR polyester is proves that safety and innovation can coexist beautifully, whether in uniforms, interiors, or protective gear.

With polyester flame retardant fabrics, you are purchasing more than just fabric – you are acquiring protection, performance, and peace of mind.

FAQs

What is flame retardant polyester?

FLame retardant polyester is a specially engineered fabric that resists ignition, slows fire spread, and offers protection and durability.

How is flame retardant polyester made?

It’s created by adding flame-resistant chemicals during fiber production or applying special treatments afterwards.

Is flame retardant polyester washable?

Yes, it can be washed with mild detergent. However, treated versions may lose their effectiveness after repeated washes.