Polyester fabric is used globally across many industries like sportswear, sewing, and even furniture. It has a long history, and is a complex fabric with many factors to consider, such as: sustainability and it’s impact on the environment.

In this blog, we will discuss the diverse applications and history of polyester fabric as well as eco-friendly modifications like Eco-Polyester and the future of it.

1. History of Polyester Fabric

In 1929, Wallace Carothers, an American chemist, working for DuPont, enhanced the research of synthetic fibers by inventing polymer chains.

British chemists John Rex Whinfield and James Tennant Dickson invented polyester in 1941. It was in later 1950s that it was introduced in the US, under the brand name of Dacron. It caught on quickly due to its trademark increase in durability over other fabrics.

History of Polyester Fabric was highly used in the fashion industry during 1970s to 1980s and post 80s it lost its popularity due to comfort issues. It was on a decline for a number of years until other countries revised their production methods. Now, it is highly valued for its durability and increased comfort.

2. What Is Polyester Fabric?

Polyester is a fabric of a synthetic nature, which is created through the use of chemical compounds derived from petroleum. Its commonest type is PET (polyethylene terephthalate). It possesses important properties including, strength, resistance to stretching, shrinking and quick drying.

Polyester fabric can be;

- Woven, a versatile material used for making shirts, trousers, and curtains,

- Specifically, knitted fabrics are used for making T-shirts and other sportswear.

- Can be mixed with natural fibers like cotton or wool

3. Where Can We Use Polyester Fabric?

Polyester fabric can be found in various areas or industries.

Fashion & Apparel

Polyester works perfectly for clothing for these reasons:

- T-shirts and dresses

- Jackets

- Sportswear

- School and work uniforms

Home textiles

The many benefits of polyester make it perfect for home items:

- Curtains

- Bed linens

- Cushions

- Carpets

Industrial use

Polyester fabric is used for more than just clothes; it is also essential for industrial applications globally.

- Seat belts

- Ropes

- Sails

- Conveyor belts

Outdoor gear

In terms of outdoor recreational activities, polyester fabric is unrivaled

- Tents

- Back packs

- Sleeping bags

Its water resistance, strength, and low cost make it a favorite for both fashion and function.

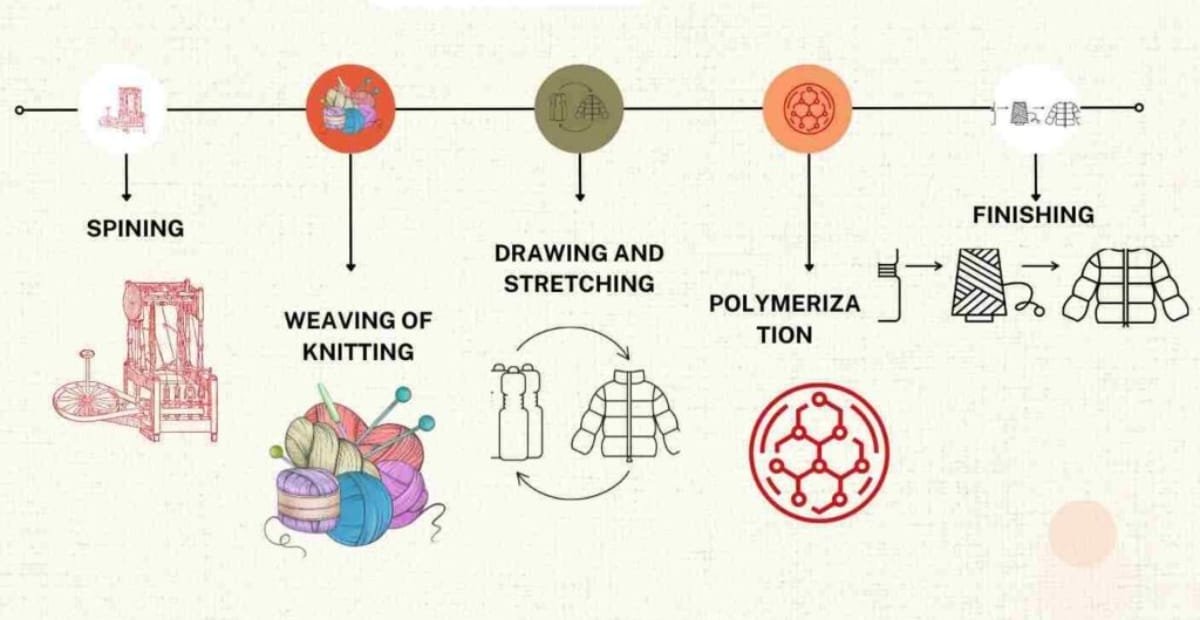

4. Making Process of Polyester Fabric

Making Process of Polyester Fabric First, in the Polymerization stage, ethylene glycol and terephthalic acid are chemically reacted to form PET. Then, the PET is melted into a liquid in the melting stage. Finally, the liquid form of the PET is extruded through spinnerets to create long fibers in the extrusion stage.

- Spinning: Fibers are converted into yarns through spinning.

- Cooling & Cutting: Fibers are either cooled and cut into staples or are filament-wound.

- Weaving/Knitting: Yarn fabrics are produced using looms and knitting machines.

- Finishing: Finishing Softening and renderring fabric resistant improves its quality, further treating, dyeing, and printing the fabric enhances its properties.

5. Biggest Producers of Polyester Fiber

Asia is the primary producer of polyester, the largest producers are:

- China (world’s largest manufacturer)

- India

- japan

- Taiwan

- Indonesia

These countries export polyester to global textile markets, powering industries from fashion to furnishings.

6. Types of Polyester Fabric

These are the different types of polyester fabric:

1. PET (Polyethylene Terephthalate)

PET (Polyethylene Terephthalate) Used the most among textiles and bottles.

2. PCDT (Poly-1,4-cyclohexylene-dimethylene terephthalate)

PCDT Used of heavier fabrics like curtains or upholstery.

3. Recycled Polyester (rPET)

Recycled Polyester (rPET) Its produced from old garments and plastic bottles, it’s less harmful to the environment and more popularly used.

4. Microfiber Polyester

Microfiber Polyester used is Towels, bed linens, and cleaning cloths are super soft.

7. Certification Types for Polyester

These certifications can be awarded to polyester fabrics to ensure the quality and sustainability:

- OEKO-TEX Standard 100 – Certification states that the fabric does not contain harmful substances.

- Global Recycled Standard (GRS) – Confirms recycled polyester content.

- Recycled Claim Standard (RCS) – Monitors recycled content in the supply chain.

- Bluesign® Certification – Guarantees noteworthy social responsibility in manufacturing.

8. Environmental Impact of Polyester

Polyester is one of the few substances that is not biodegradable. Its decomposition can take hundreds of years, and the shedding of microplastics during washing is an additional insult, polluting the oceans.

Recycling does help this issue to an extent. Giving old plastics a new purpose, recycled polyester (rPET) mitigates some of the damage.

Outside efforts to make the production of polyester more eco-friendly include:

- Renewable energy use in manufacturing plants

- Recycling of plastics, such as bottles

- Closed-loop production systems

9. Is Polyester Cheaper Than Cotton?

Generally speaking, polyester is cheaper than cotton.

Why?

- Polyester is cheaper to manufacture.

- The product lasts longer.

- The production of polyester requires fewer resources, such as water.

While cotton work jacket remains softer and more breathable, polyester has the advantage of affordability, durability, and effective moisture-wicking.

Final Thoughts

The textile industry considers polyester a powerful fabric. Indeed, its strength, versatility, and affordability are unmatched. The environmental concerns are there, but options for recycling are available.

Therefore, with a focus on sustainable fashion and the rise of Eco-Polyester and rPET, textiles have a more environmentally friendly future.

FAQS

Is polyester breathable?

Not as breathable as cotton, but more recent innovations have enhanced its ventilation.

Can polyester be ironed?

Polyester can indeed be ironed, but requires low settings. High temperatures will damage the fibers.

Does polyester shrink?

Shrinking and stretching are two things polyester resists.