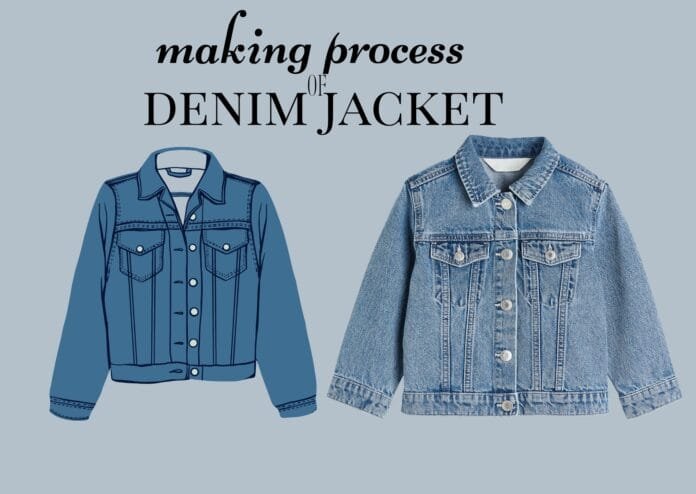

Denim jackets are not just stylish—they are also the result of a detailed process that combines craftsmanship and technology. The making process involves several steps, from selecting raw materials to finishing touches that create the final product. Making Process of Denim Jackets

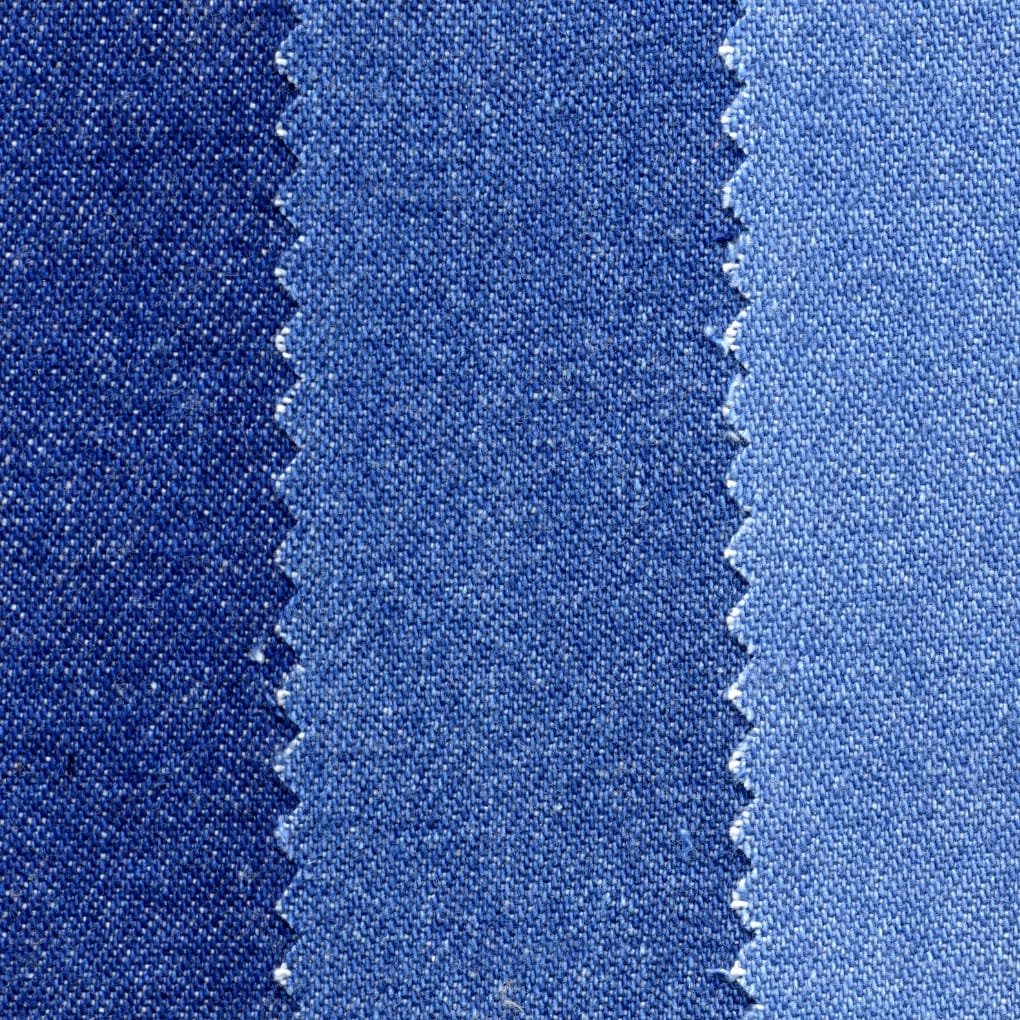

1. Raw Material Selection

The creation of denim jackets starts with selecting the right raw materials, and at the heart of this process is cotton. Cotton serves as the primary fiber, the fundamental building block, if you will, for the denim fabric that will ultimately become the jacket. The type of cotton chosen is of paramount importance; opting for high-quality cotton is not merely a preference, but a necessity. This is because the quality of the cotton directly influences several key characteristics of the final denim product. Specifically, high-quality cotton guarantees a robust level of strength in the denim, ensuring that the jacket can withstand regular wear and tear without easily ripping or tearing. Furthermore, it contributes significantly to the overall durability of the jacket, meaning it will last longer and maintain its integrity over time, even with frequent use and washing. Finally, and perhaps most importantly from a wearer’s perspective, high-quality cotton provides a superior level of comfort, making the denim jacket pleasant to wear against the skin and allowing for breathability and ease of movement. In short, the selection of high-quality cotton is a foundational step in producing denim jackets that are strong, durable, and comfortable for the wearer. Making Process of Denim Jackets

2. Yarn Production

The artist meticulously transforms raw cotton fibers into a delicate thread. This initial process requires a skilled hand and keen eye to ensure the resulting thread is of the highest quality. Once spun, the thread is carefully wound onto a cone. This winding process is a crucial step in preparing the thread for its ultimate purpose: the creation of a painting canvas. The cone shape allows for easy dispensing and prevents tangling, ensuring a smooth and even flow of thread during the canvas construction. The creation of a long-lasting canvas demands thread that is both smooth and taut. These qualities are essential for the structural integrity of the artwork, preventing sagging or warping over time. Only by using smooth, taut thread can the artist guarantee the longevity and enduring beauty of their painted masterpiece. Making Process of Denim Jackets

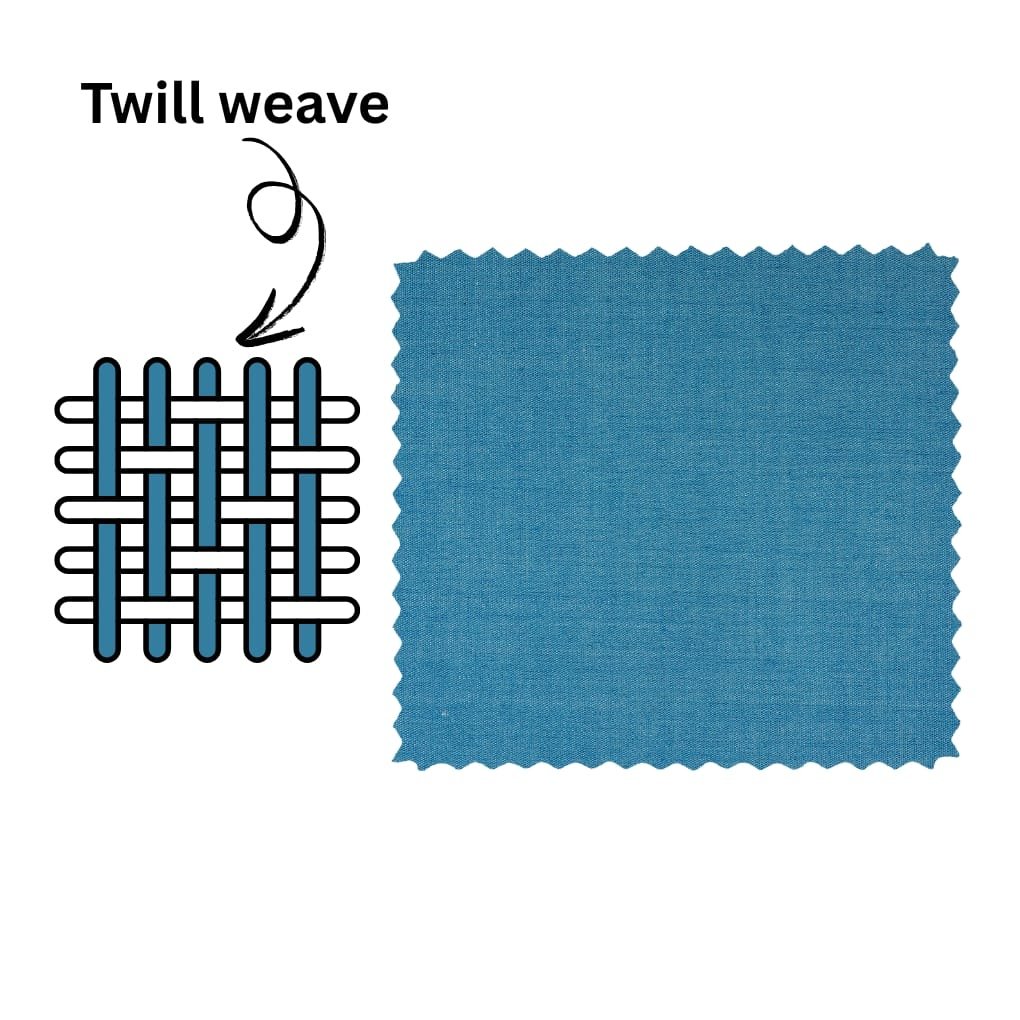

3. Weaving the Denim Fabric

Twill weave is a distinctive weaving pattern frequently employed in the creation of denim fabric, lending it both its characteristic diagonal ribbing and inherent robustness. This particular weaving technique involves a specific arrangement of yarns. The warp yarns, which are typically dyed with indigo to achieve the deep blue hue associated with denim, are interlaced with the weft yarns, which are often left in their undyed, natural state. This interweaving process results in the warp yarns passing over the weft yarns in a consistent, repeating pattern. It is this interplay between the dyed warp yarns and the undyed weft yarns that ultimately produces the recognizable blue-and-white appearance that is so strongly associated with classic denim. The diagonal lines, a hallmark of twill weave, contribute not only to the fabric’s visual appeal but also to its enhanced durability and resistance to wear and tear, making it a popular choice for garments intended for long-lasting use. Making Process of Denim Jackets

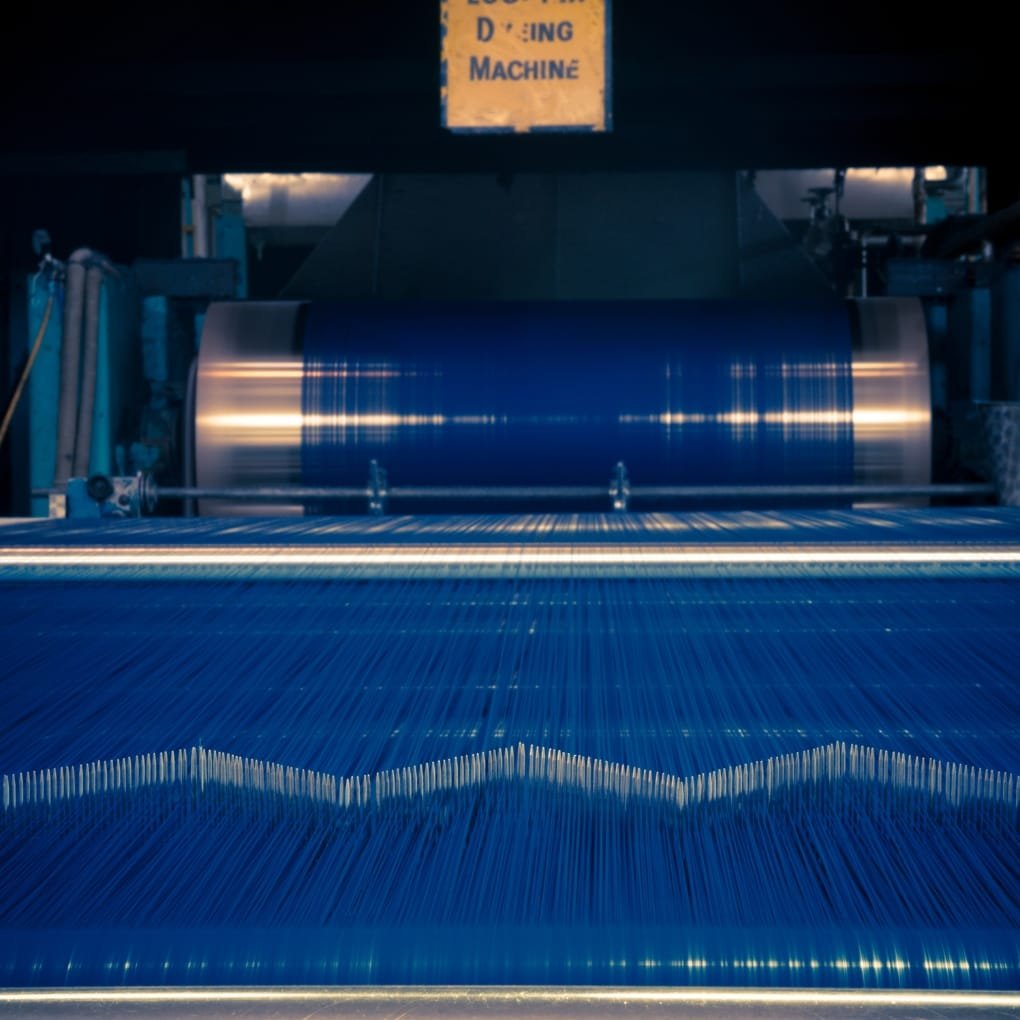

4. Dyeing Process

For the warp threads, dyers use indigo, a colorant that can be sourced from natural origins or produced synthetically. Traditionally, the process of achieving the desired rich, deep blue shade was quite involved, often necessitating a repeated sequence of immersions in an indigo dyeing vat. This multiple-dip method was essential to building up the color intensity, as each submersion contributed another layer of indigo pigment to the yarn. The precise number of dips varied depending on factors such as the concentration of the dye bath and the specific shade of blue sought after by the artisan. Consequently, the dyeing procedure could be a lengthy and laborious undertaking, demanding considerable skill and patience to attain the correct and consistent coloration for the warp threads.

5. Cutting the Fabric

The journey of denim fabric takes a significant turn when it arrives at garment factories. Having already been meticulously woven and expertly dyed, the denim now enters a new phase of transformation. Within the factory walls, skilled workers prepare to convert the raw fabric into recognizable garment components. The initial step involves carefully marking patterns onto the denim. These patterns serve as precise guides, outlining the various pieces that will eventually form finished garments like jackets. Following the pattern marking, the fabric is then carefully cut. This cutting process separates the denim into distinct sections, creating individual parts such as sleeves, collars, and the main body panels Making Process of Denim Jackets. Each piece is cut with precision, ensuring that they meet the required dimensions and specifications for assembly.

6. Sewing and Assembly

The process of joining the various cut denim components involves the use of robust, heavy-duty machinery specifically designed for this purpose. These machines meticulously stitch the individual pieces together, creating a cohesive whole. The strength and durability of these seams are of paramount importance, as denim is known to be an exceptionally tough and resilient fabric. Given the fabric’s inherent durability, the seams must be equally robust to withstand wear and tear. The assembly stage also encompasses the addition of crucial details to garments such as jackets. This includes the precise attachment of functional elements like buttons, which provide closure, and zippers, which offer an alternative fastening method. Furthermore, pockets are carefully integrated into the design, providing practical storage solutions and enhancing the overall utility of the finished product. Making Process of Denim Jackets

7. Washing and Finishing

Following the stitching process, the jacket proceeds to the washing stage, a crucial step in determining its final appearance and feel. Various washing techniques are employed by manufacturers to create a diverse range of textures and styles. Among these techniques are stone washing, a process that utilizes abrasive stones to create a worn and softened effect; enzyme washing, which uses enzymes to alter the fabric’s surface, resulting in a smoother texture and faded appearance; and distressing, a technique that intentionally creates imperfections and a vintage look. These methods allow for significant customization of the jacket’s aesthetic. Beyond washing, the jacket receives additional finishing touches that further enhance its design and branding. These finishing touches commonly include the addition of embroidery, providing decorative detailing and personalization; the attachment of labels, which serve to identify the brand and provide care instructions; and the application of patches, offering another avenue for customization and the addition of unique design elements.

8. Quality Control

During the inspection process, denim jackets undergo thorough scrutiny to ensure the stitching accuracy meets the required standards. The inspectors also carefully examine the fabric quality of the denim jackets to identify any defects or inconsistencies. Furthermore, the finishing of the jackets is assessed to ensure it meets the desired specifications. It is only those denim jackets that successfully pass this comprehensive inspection procedure that are permitted to move forward in the production process.

9. Packaging and Distribution

Once the manufacturing process for the jackets is complete, the company meticulously ensures each one is properly prepared for distribution. This involves a thorough ironing process to remove any wrinkles or creases that may have formed during production. Following the ironing, the jackets are carefully folded to maintain their shape and prevent damage during transit. Each jacket is then individually packaged to protect it from the elements and ensure it arrives at its destination in pristine condition. After packaging, the company undertakes the crucial step of distributing the finished jackets to a wide network of retailers located across the globe, making them available to customers worldwide.

Conclusion

The creation of a denim jacket represents a blend of time-honored craftsmanship and contemporary technological advancements. The journey of a denim jacket, beginning in cotton fields and culminating in its display within fashion stores, involves a series of meticulous steps. Each stage of this process contributes to the jacket’s overall value and enduring style. The transformation from raw materials to a finished garment requires precision and expertise. This deliberate and attentive process ensures that denim jackets consistently maintain their reputation for durability, fashionable appeal, and timeless quality. From the selection of the cotton fibers to the final stitching and finishing touches, every element is carefully considered. The jacket’s robust construction guarantees longevity, while its design reflects current trends and classic aesthetics. The enduring popularity of the denim jacket is a testament to the successful combination of quality materials, skilled manufacturing, and enduring style. The entire production chain is designed to deliver a product that is both practical and aesthetically pleasing, making it a staple in wardrobes across generations.

FAQS

What material is used to make denim jackets?

Cotton yarn usually weaves denim jackets in a twill pattern. Sometimes polyester or elastane is added for flexibility and durability.

How are denim jackets dyed?

The warp yarns are dyed with indigo, while the weft yarns remain white. This gives denim its signature blue exterior and lighter interior.

What is the most important step in making a denim jacket?

Each step is important, but weaving and dyeing are key because they create the strength, look, and texture of the denim fabric.