Polyester is another easy fabric to use in everyday wear and custom clothing particularly in heat pressing. Polyester has to be heat-pressed carefully and with attention so as not to ruin the cloth. Could you therefore heat-press polyester? Yes, however, you have to be guided by specific guidelines, which can guarantee best performance. This paper will discuss the best heat press methods when using polyester, temperature settings, methods that should be used and the pitfalls to avoid.

Can You Heat-Press Polyester?

It is possible to heat-press polyester but this must be done with special consideration because it is heat sensitive. Polyester is a synthetic cloth produced out of polyethylene terephthalate (PET), and even though it is a strong material, it is not that difficult to melt when compared to other fabric materials such as cotton. Exposing polyester to high temperatures over a long duration may cause it to melt or deform and this may destroy your garment.

Raising polyester through heat pressing is done by placing the heat and pressure on the fabric by use of a heat press machine. Polyester however requires low temperature compared to cotton or other natural fibers. It is possible to heat press polyester successfully without destroying it with by heeding the correct heat settings and methods.

What Temperature to Heat-Press Polyester?

Ideal Temperature Range (e.g., 270°F–300°F / 132°C–149°C)

The recommended range of heat pressing polyester is usually between 270F and 300F (132 C -149 C). Polyester will not melt or scorch because of these temperatures. One should not be outside this range as it will damage the fabric.

Why Polyester Requires Lower Heat Than Cotton

Polyester is a synthetic garment and fibers are more vulnerable to heat. Polyester fibers also start to disintegrate above 320 o C (160 o F) unlike cotton, which remains stable at temperatures up to 60 o C. That is why it is necessary to make some changes in the temperature and do not use the same settings as with cotton.

Does Polyester Melt Under Heat Press?

Risks of Scorching, Melting, or Leaving Shiny Marks

High heat may cause polyester to melt, when over a prolonged period. In case the temperature surpasses its melting point, the fibers will start to melt, which means that the fabric will melt or leave permanent shiny spots. These spots can destroy the outlook of the design and the fabric itself.

Signs That Polyester Is Overheating

What do you do to know whether polyester is being damaged during pressing? Watch out for these signs:

- Glossy Sheen or Discoloration: Which is a characteristic sign: A shiny or yellow-colored spot of where the press was. The burnt polyester produces a shine on fabric. When you notice a clear or shiny part then the polyester is overheating.

- Stiff or Melted Feel: Rub your hand on the pressed area. In case the cloth is stiff or sticky, it is partially melted.

- Odd Smell: A weak chemical smell or a burning smell may be a sign of melting of polyester fibers.

- Print Issues: It may not stick or even be dull when transfers have been damaged.

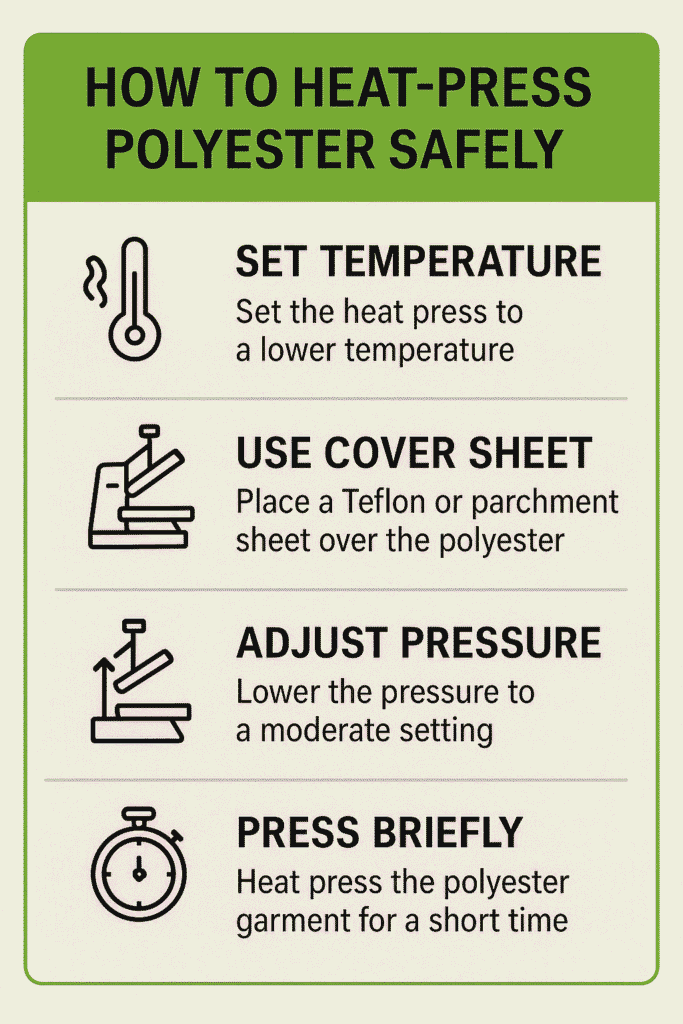

Step-by-Step Guide: How to Heat-Press Polyester Safely

Preparing the Fabric

Preparation of polyester fabric: The polyester fabric should be prepared. This involves pre-pressing of the cloth to dry out the wrinkles and the moisture. The presence of moisture may disrupt the heat transfer mechanism and give inconsistent outcomes.

Choosing the Right Heat Transfer Vinyl (HTV) or Sublimation Method

Choose a type of transfer that is appropriate with polyester. A heat transfer vinyl (HTV) with a lower heat requirement – such as a stretch or low-temperature vinyl – should be used where the graphic or lettering to be applied is solid-color. In case of an image that contains a lot of colors or a photographic design, sublimation on white or light polyester shirt can be considered. Sublimation ink evaporates (evolves into gas) and leaks into polyester fibers providing vivid effects. Standard vinyl cuts, on the contrary, are placed over the fabric.

Recommended Temperature, Pressure, and Pressing Time

Heat your heat press device to between 270o F and 300 o C(132 C-149 C). The pressure ought to be medium to firm with the duration of pressing at approximately 10-15 seconds. The best results will be obtained by always referring to the individual recommendations on the vinyl or transfer paper.

Best Heat Transfer Vinyl for Polyester

Regular HTV vs. Stretch HTV

HTV is available in two general categories, which are standard (regular) and stretch vinyl. Standard HTV is heavier and is still in form in non stretch fabrics; stretch HTV is lighter and is designed to stretch. stretch HTV tends to be more suitable on polyester particularly poly blend athletic wear. When you use normal HTV on a loose polyester shirt, the vinyl can crack when the garment is put into motion.

Stretch HTV is intended to work with performance fabrics: it can bend with the piece of clothing and does not crack. Standard HTV would work fine with the purely cotton shirts, but the stretchiness of polyester (even a slight stretchiness) requires the use of stretch vinyl. Thus, select a stretch or performance vinyl movie when your polyester garment is flexible, or when it is termed sports or moisture-wicking apparel.

Which HTV Types Bond Better with Polyester

Polyester bonds with glitter HTV, matte HTV and high-heat transfer vinyl. These kinds of HTV are designed specifically to be applied on the synthetic fabrics such as polyester giving them a smooth finish, without tearing the fabric.

Can You Sublimate on Polyester?

Difference Between Sublimation and Heat Pressing with HTV

Sublimation and heat-transfer vinyl (HTV) are highly dissimilar processes. In sublimation, you take an image and print it on a special paper and then heat the paper and apply dye to the fibers in the fabric. In comparison, HTV involves a solid vinyl film, which is cut in shapes and pressed onto the cloth.

Significant variations: Sublimation can be applied to polyester surfaces (or poly-coated), and it gives photo-quality and full-color images that become a part of the fabric. Sublimation cannot be done on plain 100 percent cotton without any special treatments. Polyester, cotton, nylon, and others can be subjected to HTV since it is a coating over the material. Concisely, sublimation prints are impregnated inside polyester fibers, and HTV designs are placed on top of the fabric and typically peeled off once the printing process has been done successfully.

Why Sublimation Works Best with Polyester

Polyester is the best material to use in Sublimation since the ink chemical bonds with the polyester fibers when it is exposed to high temperatures. The porous nature of the polyester enables absorption of the ink more, giving rise to the vibrant and long lasting designs.

Heat Press Settings for Polyester Blends

Polyester-Cotton Blends vs. 100% Polyester

Mixed fabrics (such as 50/50 poly-cotton) are midway between pure polyester and pure cotton in the heat resistance. The greater the cotton content, the more you can afford rather high temperatures, but too big a proportion of polyester in the fabric and you must be cautious. Approximately 300-350 F can be the lowest temperature that a poly-cotton mixture can support, and the lowest temperature at which 100% polyester should be kept is 270-300 F. As an example, a medium temperature of 325F/15sec could be applied to a 50/50 mixture.

But you must not plunge at once at all into a polyester-laden blend. Begin on the lower side of the intermediate range and test. It is important to keep in mind that heat sensitivity is also influenced by the other variables (fabric weight, dye, finish), which means that one should always look at the garment as a whole rather than only at the ratio of fibers.

How to Adjust Settings Based on Fabric Mix

When working with a polyester-cotton mixture, turn the temperature to the lower part of the recommended range and use medium pressure. It is always good to test a patch first so that it does not ruin the cloth.

Common Problems When Heat-Pressing Polyester

Fabric Discoloration

Polyester fabric may become yellowish when overheated or pressed too long; it may also develop splotchy spots. This occurs at the stage when the artificial fibers begin to scald. The solution here is prevention: one must always use a lower temperature and squeeze the shirt to get the moisture out. In case of a small discoloration, you can attempt the light ironing (without vinyl) on the other side, with a protective sheet, which can decrease the appearance. Severe discoloration however is normally permanent- test on scraps and take settings gentle.

Adhesive Not Sticking

When the vinyl or transfer cannot stick well, it usually happens that the settings were too low or the materials were not of the right nature. On polyester, make sure you have transferred using a polyester compatible vinyl or sublimation transfer. Then maintain a sufficient time, temperature and pressure. As an example, add a couple of seconds to press time or add a little more pressure. The teflon or parchment sheet would be useful in distributing heat equally. In case even a dark poly-cotton shirt will not take vinyl, then try a quick pre-press at the suggested temperature to simply get the fibers to set.

Fabric Scorch Marks

Scorch marks occur despite the care. These appear as hard and shiny spots or visible press impressions. To repair light scorching, either a cool iron or easy-press will work on the back side: press carefully in circles around the scorch mark in small circles to feather out the one. This will not entirely fade out the mark, but it may be let in the fabric. To the next generation presses, then certainly reduce the temperature or time.

Pro Tips to Avoid Damaging Polyester

Teflon Sheet/Parchment Paper

A Teflon sheet or parchment paper should always be between the heat press plate and the fabric. This improves the resistance of the polyester to direct heat and avoids any possible damages.

Pre-Pressing to dry off the Moisture

Wet the fabric in a few seconds and squeeze out all the water. This makes sure that the fabric is not wet and is ready to undergo heat transfer causing increased adhesion.

Lower Temp + Longer Press Trick

In case of problems with cloth damage, use low temperature and maximum time. This helps avoid overheating of the cloth and at the same time enables the transfer to bond effectively.

Heat-Press vs. Iron on Polyester

What is the Best Method in Durability?

The durability of heat pressing is superior to ironing. A heat press offers pressure and temperature in an even and consistent manner, giving a stronger and more professional outcome and lasting longer.

The reason why a Heat Press provides professional results

Heat press machine ensures uniformity of temperature and pressure which aids in ensuring that the transfer is evenly stuck and firmly attached to the polyester. On the other hand, irons are not precise and may cause uneven application.

Polyester vs. Cotton Heat Pressing

Polyester has lower temperatures than cotton owing to its synthetic nature. Cotton is able to withstand more heat than polyester which is highly susceptible to melting or shiny spots when subjected to excess heat. So, it is important to always use a lower heat setting when using polyester.

Conclusion-

So, can you heat-press polyester? But, yes, very careful and very precise. Polyester is extremely sensitive to heat, and this fact requires lower heat and protective layers. Professional and long-lasting results should be achieved after following the suggestions of experts like pre-pressing, Teflon sheets, and the choice of the HTV. Polyester is a great medium to use in creative designs safely using heat in both sublimation and vinyl transfer processes.

When you do the do and avoid the dons, it is possible to heat-press polyester without damages. Always keep in mind- less heat, more care and the technique is the key to success.

FAQs

Can you heat-press polyester at 350°F?

No, polyester cannot withstand 350 o F. The fibers start melting or scalding at this high temperature. The temperature should not exceed 270 o F -300 o F as permanent damage to the

Will polyester shrink under heat press?

fabric may occur.

Polyester does not shrink like cotton, but still, it is vulnerable to damage. Even high temperature can lead to warping or falling of shape of the fabric. That is why consideration of the temperature is crucial.

How long should you press polyester?

At lower heat levels, the optimal pressing time is 10-15 seconds. Excessive pressing can heat the cloth, which will lead to poor adhesion. Vary time depending on the type of vinyl.

Polyester is the best material to use in sublimation as the fibers take sublimation ink directly.

Is polyester better for sublimation or vinyl heat transfer?

Nevertheless, the stretch HTV is also adhesive when pushed under the right temperature and pressure. Each of the two approaches is effective when used appropriately.