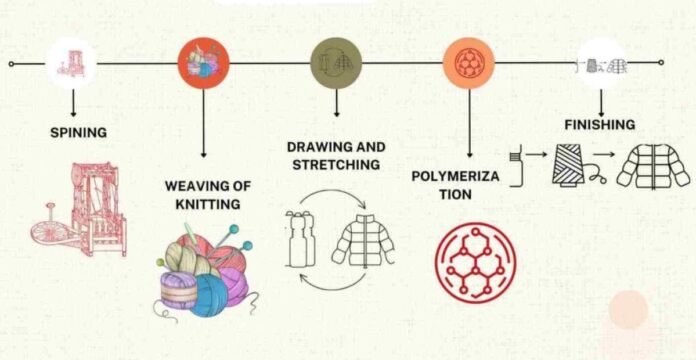

Known for its strength, durability, and affordability, it plays a big role in fashion, home textiles, and industrial applications. The answer lies in two main processes: weaving and knitting. Both methods use polyester yarns but result in very different types of fabrics. Let’s explore each process step by step. Polyester Fabric Making: Weaving and Knitting Process Explained.

Understanding Polyester

Polyester is a synthetic fiber made from petroleum-based polymers. It is created through a chemical reaction called polycondensation, which produces long chains of polyethylene terephthalate (PET).

Polyester Fabric Weaving Process

It involves interlacing two sets of yarns at right angles.

Steps in Polyester Weaving

- Warping – Polyester yarns are arranged vertically on a loom to form the warp.

- Weft Insertion – Another set of polyester yarns is passed horizontally through the warp using shuttles or modern air-jet looms.

- Interlacing – The warp and weft interlace at right angles to form a tightly bound fabric structure.

- Finishing – The woven fabric undergoes processes like heat setting, dyeing, and finishing to enhance strength, colorfastness, and texture.

Characteristics of Woven Polyester

- Strong and durable

- Resistant to wrinkles

- Holds its shape well

- Commonly used in shirts, trousers, jackets, upholstery, and industrial fabrics

Polyester Fabric Knitting Process

Knitting is a more flexible method that creates fabric by interlooping polyester yarns. This results in a stretchier and softer textile compared to woven fabrics.

Steps in Polyester Knitting

- Yarn Preparation – Polyester filaments are wound onto cones or spools.

- Loop Formation – Using needles, the yarns are interlooped to form rows of stitches.

- Machine Knitting – Industrial circular or flat knitting machines are used to produce fabric quickly and in large quantities.

- Finishing – The knitted fabric is heat-set, dyed, and treated to improve softness and stability.

Characteristics of Knitted Polyester

- Stretchy and flexible

- Comfortable to wear

- Lightweight and breathable

- Commonly used in t-shirts, sportswear, activewear, socks, and casual dresses

Weaving vs Knitting in Polyester Fabric

| Feature | Woven Polyester | Knitted Polyester |

|---|---|---|

| Texture | Firm and structured | Soft and stretchy |

| Durability | Highly durable and wrinkle-resistant | Comfortable but may lose shape over time |

| Production Speed | Fast on industrial looms | Moderate, depends on machine type |

| Uses | Formal wear, upholstery, uniforms | Activewear, t-shirts, sportswear |

Why Polyester Works Well in Both Methods

Polyester’s strength, versatility, and adaptability make it suitable for both weaving and knitting. Whether woven for durability or knitted for comfort, polyester remains a top choice for manufacturers and consumers alike.

Conclusion

The making of polyester fabric through weaving and knitting highlights the versatility of this material. Woven polyester is strong, structured, and long-lasting, while knitted polyester is stretchy, soft, and comfortable. Together, they cover a wide range of applications, from fashion and sportswear to home textiles and industrial use.

Understanding these processes not only helps us appreciate the fabrics we wear but also shows why polyester continues to dominate the global textile industry.

FAQS

What is the difference between woven and knitted polyester?

Woven polyester is firm, durable, and wrinkle-resistant, while knitted polyester is stretchy, soft, and comfortable. The choice depends on the fabric’s purpose.

Is woven polyester stronger than knitted polyester?

Yes. Woven polyester has a tighter structure, making it stronger and more resistant to wear. Knitted polyester, while softer, can lose shape over time.

Which type of polyester is better for sportswear?

Knitted polyester is better for sportswear because it is flexible, breathable, and allows free movement. This is why it’s common in t-shirts, leggings, and activewear.