Cotton has shaped human life for thousands of years. Farmers grow it, industries process it, and people wear it every day. The cultivation of cotton connects agriculture with fashion, making it one of the most important natural fibers in the world. From fields to fabrics, cotton’s journey is fascinating and essential.

Early Steps in Cotton Farming

The journey begins in the fields. Farmers carefully prepare the soil for planting at the right seasonal moment. Optimal soil structure and nutrient balance, along with effective agronomic practices, set the stage for robust biomass accumulation. In cotton cultivation the emphasis is always on sustained plant vitality, since each seed, when tended, carries the capacity to become garment closeness to lives around the globe, linking tactile comfort to agricultural intent. One seed, one plant, one bore, one ball.

Growing Cotton Plants

After sowing, heat, moisture, and light initiate seed metamorphosis. Farmers monitor the micro-conditions of the canopy, managing insect populations and competing weeds with calibrated inputs of labor and, when warranted, low-toxicity agents. This stage of development is an act of engineered duets, waiting for the tender white apical flowers, followed by the signature epidermal fibers, to emerge compressed in unopened bolls that promise an expanding industry between memory and the present.

Harvesting Cotton Bolls

When the bolls mature, they open to expose creamy-white locks, gleaming under the midday sun. Workers, then, are faced with the choice of clipper or glove. Clipping is laborious, coaxing each fiber to the length at which strength resides. However, wide-row self-automated harvesters advance, gathering entire paddocks with mechanical arms. The crop is carried to trailers, and with it the plant’s responsible life-cycle begins to close.

From Fields to Ginning

Delivered to the gin yard, the cotton is festive with green husk and stubborn burr. Gigantic, modular gins attack the mass, blowing and crushing until loose fiber, seed, and chaff part company. Eddy sieves and vibrating screens force separation at speed, presenting bales of clean cotton ready for destiny. The gin does not merely clean; it calibrates the fiber length, seed-profile, and moisture level, all preconditions before the riot of spinning machines promised in the great sheds along the railway.

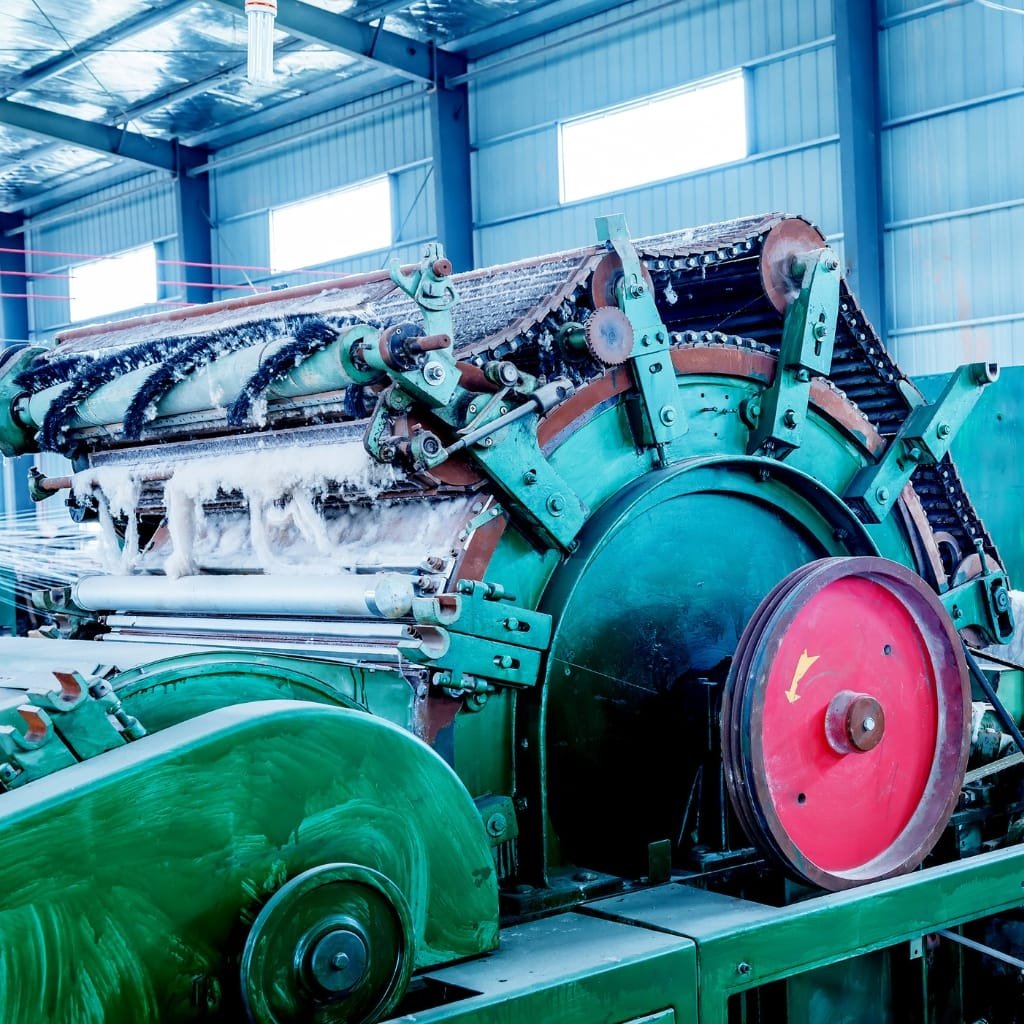

Spinning the Fibers

Into the spinning plant, the bales are unwound, carded, and drawn, then recombined through roving frames. An unseen pedantry of countless rollers and traveler rings pit the short fiber bundles against twisted anchoring cords of steel; yet, the cotton, suffering no indignity, emerges in fine, lustrous lengths of ring-spun yarn, the first, yet attested seed of fabric. Therefore, the plant and the mechanical inseparably connect, the cultivation still laboring on through iron, speed, and craft to supply yarn ready for the arms of every loom around the globe.

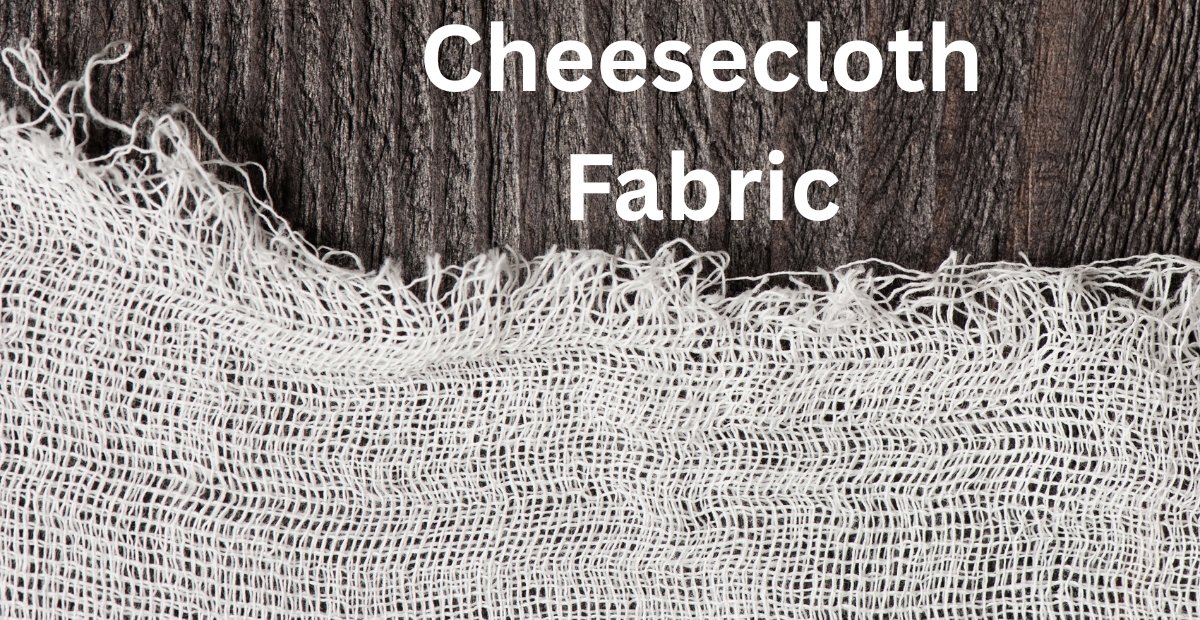

Weaving and Knitting Fabrics

Yarns then proceed to weaving or knitting to transform them into fabric. Weaving interlaces warp and weft threads at right angles to form flat cloth, while knitting interlocks successive loops of a continuous yarn. Each technique bestows distinct aesthetic and physical properties. Throughout this process, superior cotton fibers—characterized by uniform diameter and minimal defects—yield fabrics that are both soft to the touch and mechanically resilient. At this point, cotton assumes its definitive, usable morphology.

Dyeing and Finishing

The newly woven fabric typically presents a subdued, uniform surface. To enhance its visual and tactile appeal, the cloth is subjected to dyeing and finishing. Dyeing introduces chromatic complexity, while finishing operations—such as softening, mercerizing, or applying protective coatings—impart functional enhancements, including increased smoothness, crease resistance, and abrasion resistance. The intrinsic affinity of high-quality cotton for reactive dyestuffs allows for brilliant and durable coloration. The modification of cotton fibers, then, is indispensable for ensuring that textiles maintain both aesthetic luster and tactile comfort over extended use.

Cotton in Everyday Life

Cotton textiles are ubiquitous in contemporary environments, seamlessly integrating into domestic, educational, medical, and industrial settings. The fiber manifests in a multitude of applications, from garments to bed linens, window treatments to laboratory coats. Its enduring appeal is rooted in an exceptional balance of comfort, durability, and ease of care. The agricultural ecosystem that cultivates cotton continues to support this expansive horizon of use, ensuring that the fiber remains an indispensable resource for both manufacturers and consumers, its societal significance undiminished.

Challenges in Cotton Farming

Raising cotton in today’s climate entails an array of persistent obstacles. Limited access to irrigation, aggressive pest populations, and historically unpredictable weather patterns combine to threaten field stability. To mitigate yield loss, producers increasingly adopt advanced agronomic and technological solutions. Cotton cultivation, therefore, evolves into a continuous process of monitoring, recalibrating, and intervening. Yet, even in the face of uncertainty, the dedication of farmers ensures that this vital raw material remains available.

Sustainable Cotton Practices

The contemporary value chain progressively champions agricultural stewardship. Practices such as certified organic soil management, precision irrigation strategies, and integrated pest management contribute to lower environmental footprints. These measures simultaneously enhance the safety of farmers and the ecological systems on which cultivation depends. By embedding sustainability into cotton cultivation, the industry secures both environmental integrity and the sustained capacity to fulfil global demand. Such equilibrium remains a cornerstone of future production planning.

Cotton and the Global Economy

Beyond agronomic circles, cotton fabric is a cornerstone of the international marketplace. Production, processing, and trade networks in numerous countries hinge on a coordinated eco-political web. Textile manufacture, dyeing, and garment retail further amplify downstream economic value, propelling millions into formal and informal employment. By delivering consistent output, cotton generation guarantees export revenues and supports the economic and social fabric of diverse communities. Consequently, the fibre continues to serve as both an economic engine and a repository of cultural heritage.

Cotton’s Cultural Importance

Cotton transcends mere economic value, resonating deeply within the cultural fabric of numerous societies. Handwoven saris, ancestral quilts, and seasonal rites draw largely on homespun cotton. Communities link the fibre with harmony, everyday solace, and the slow rhythm of domestic life. By yielding cloth, the crop nourishes these customs, binding lineage and contemporary experience in one softly extending strand.

The Future of Cotton Production

Scientific inquiry and technological refinement keep cotton husbandry in a steady forward arc. Breeder-devised seed with enhanced resilience gives farmer and field a more secure story, while robotics quicken harvest with a silent labour. Globally, farming now welcomes increasingly rigorous, ecological disciplines. In the growing mind of markets, eco-conscience and physical ease coexist. The life of cotton, from chosen ground to ready hand, is an unfinished and pacing path.

Conclusion

Cotton emerges from a minute seed, matures into supple cloth, and softly insists on daily acquaintance. The multitude of actions in field, gin, and loom bear shared, pliant weight. When seen in the round, the plant strengthens industries, grafts languages, nourishes communities, and keeps old chants attainable. Change will still arrive, but cotton, larger than annual calendar, keeps a resolute permanence. The fibre’s arc remains a persistent ode to slow unfolding, gentle shelter, and mindful care.

FAQs

What does the cultivation of cotton involve?

The cultivation of cotton involves planting seeds, caring for crops, harvesting bolls, and processing fibers into fabric.

Why is cotton important in daily life?

Cotton is soft, strong, and breathable. The cultivation of cotton supplies fabric for clothes, bedding, and many essential products.

What challenges do farmers face in cotton farming?

The cultivation of cotton faces challenges such as pests, water shortages, and changing weather, which affect crop growth and yields.